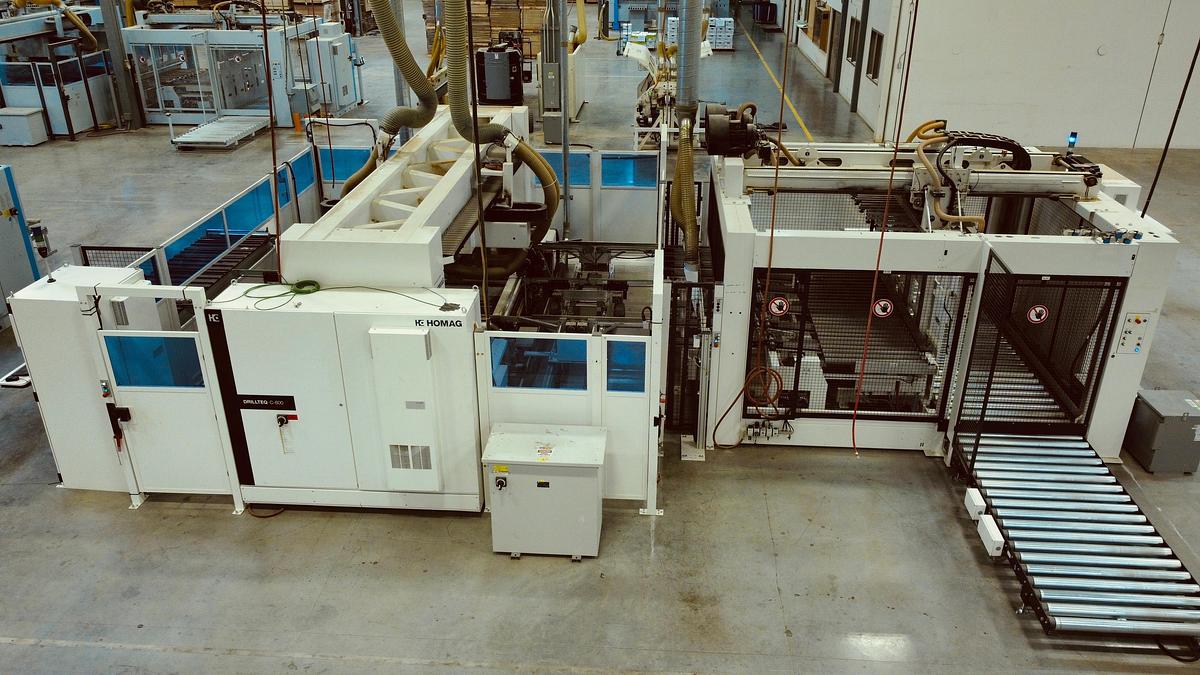

2019 Homag Drillteq C-500 / BHT500 Gantry Flexible Automatic Feed-Through Drilling Machine w/ TSH501 Unloader

2019 Homag Drillteq C-500 / BHT500 Gantry Flexible Automatic Feed-Through Drilling Machine w/ TSH501 Unloader

Available quantity:1

Description

Workpiece Dimensions: Min. 250 x 250 x 12 mm; Max. 3000 x 1400 x 60 mm (vertical/transverse edge machining width max. 680 mm min. 100 mm; Workpiece thickness max. 60 mm min. 12 mm).

Drilling Capabilities:

- 2 vertical drilling units with 38 spindles each (stroke 60 mm, drill depth max. 38 mm, rotation 1,500-7,500 rpm frequency-controlled).

- 2 horizontal drilling units with 6 spindles each (3 front, 3 rear; stroke 60 mm, drill depth max. 38 mm, right/left rotation, 1,500-7,500 rpm).

- Vertical drill gearbox with 3 spindles (fitting, 3,000 rpm, 220/380V - 50Hz, spindle distances 2x19 mm X, 7.5 mm Y, main bore XX mm).

- Horizontal drilling gearbox H21 with variable range, spindle clamping for secure depth, stroke 50 mm, max drill depth 35 mm, 1,500-7,500 rpm.

- 2 additional horizontal drilling units (motorized feed, suitable for gear 2, motorized movements).

- 2 horizontal drilling units for cup holes (fixed guide, right viewed in travel 2, height adjustment with W-axis).

- Extra charge for individual spindle call-up via program with pneumatic switching.

Grooving Capabilities: 2 grooving saw units in X-direction (cutting depth 10 mm, cross-section max. 50 mm², right rotation, 2,000-7,500 rpm, saw blade holder 30 mm, tool diameter 100 mm, thickness max. 5 mm).

Free Places: Base plate for 2 additional processing units; Config. 2V38, 2H6Y, N2, 2 free places.

Lubrication: Automatic oil central lubrication for X-axis guide carriages.

TSH501/QL/30/12 Stacker

One-sided cross-fed left-handed version for gentle, automatic transport of panel-shaped wood materials. Robust sheet steel construction. High overall availability, reduction of space requirements, secure material flow, effective layering, absolute safe parts collection in large single or double lane locations.

Workpiece and Stack Parameters:

- Workpiece Size: Min. 250 x 100 x 12 mm; Max. 3000 x 1200 x 60 mm.

- Workpiece Weight: Max. 75 kg.

- Shape: Rectangular, closed, no cutouts; Base materials: Chipboard, MDF, HDF, plywood, glued/solid wood.

- Cupping: Max. 0.2% diagonal (5 mm max); Surface: Raw, varnish, veneer, laminate, melamine, film (smooth, clean, separable, absorbent).

- Edge Material: Raw, veneer, PVC, ABS, melamine, paper.

- Feed: Lengthwise, length:width ratio max. 1:1.2.

- Stack Height: 1600 mm effective (incl. base), top edge 1900 mm from floor; Max. weight 3500 kg.

- Layer Pattern: 1- or 2-lane, 1-4 items per lane on common base; Arrangement by type; Fixed stack edge right front - QL.

- Protective Panels: Without breakouts/cutouts.

Performance Data: Based on workpiece thickness >22 mm, factor of 30 mm = 80%; Cycle time 0.2-50 seconds (changeover <50 seconds); Stack change time ~80 seconds at 1000 mm height.

Material Flow: Weeke processing machine on one side (BHT 500, 10-14 parts/min feed rate up to 60 m/min). Protective plate provision, automatic feed via roller conveyor. Collect/move aligned layers, stacking with aligned lengthwise layers and buildup, automatic run out onto downstream roller conveyor.

Stations:

- Discharge transport from processing machine: Belt transport for collecting workpieces in stacking area, automatic speed from machine, fixed left side, operation seen in conveying direction.

- Reception Transport: Pick up multi-lane stacks with roller belt for 4 layers in a row, max. layer width 1000 mm (>1 lane 2 lanes).

- Transverse: Fully equipped suction traverse for individual workpiece layers.

- Stacking Area: Designed as chain lifting platform.

- Protective Plates/Pallet Supply: Driven stacking roller conveyor with galvanized rollers, same discharge level; Carries rollers for empty pallets, automatic/manual provision.

- Renewal Stacking Transport: Driven stacking roller conveyor, height 300 +/-15 mm, speed approx. 12 m/min, stack retrieval hand switch for manual roller conveyor start.

Specifications

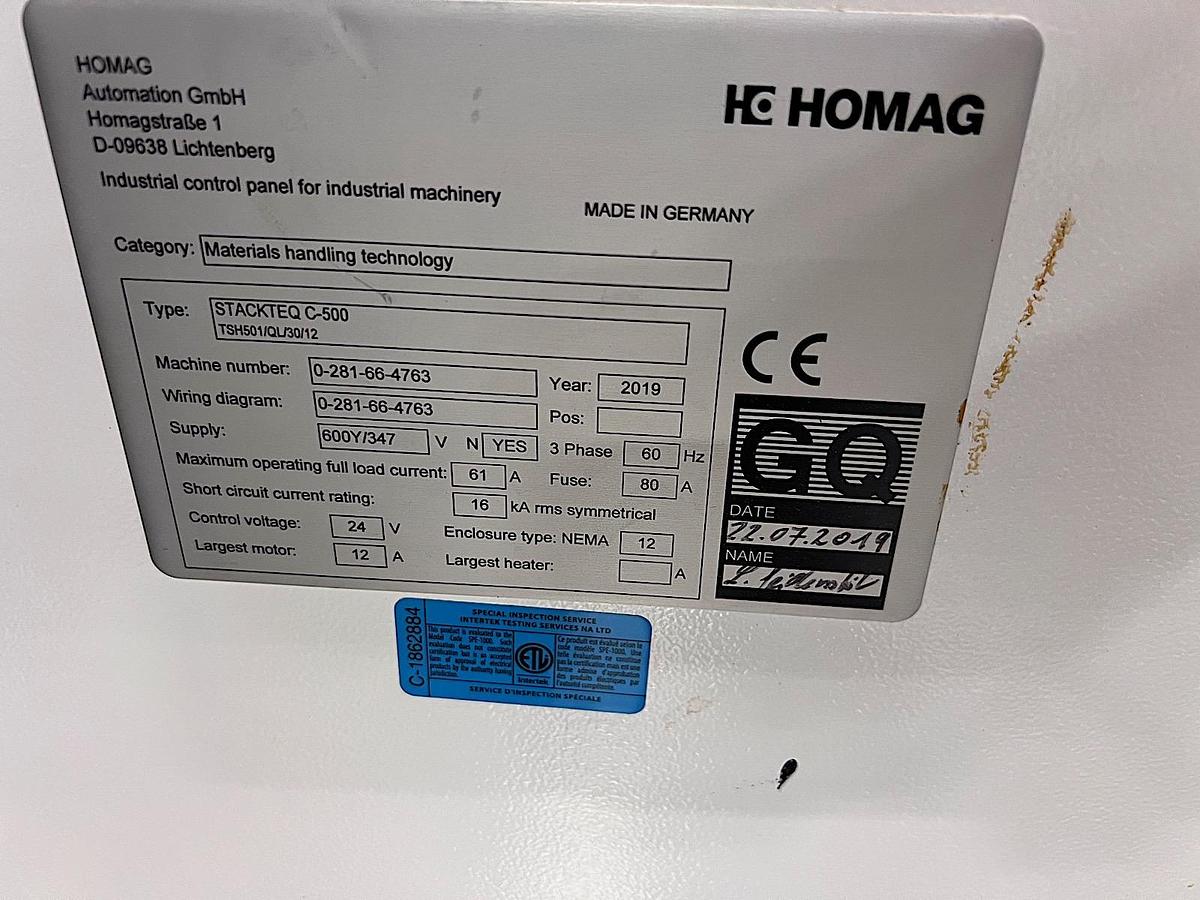

| Manufacturer | Homag |

| Model | C-500 / BHT 500 / TSH501 |

| Year | 2019 |

| Condition | Used |

| Stock Number | MA-0815230830-22 |