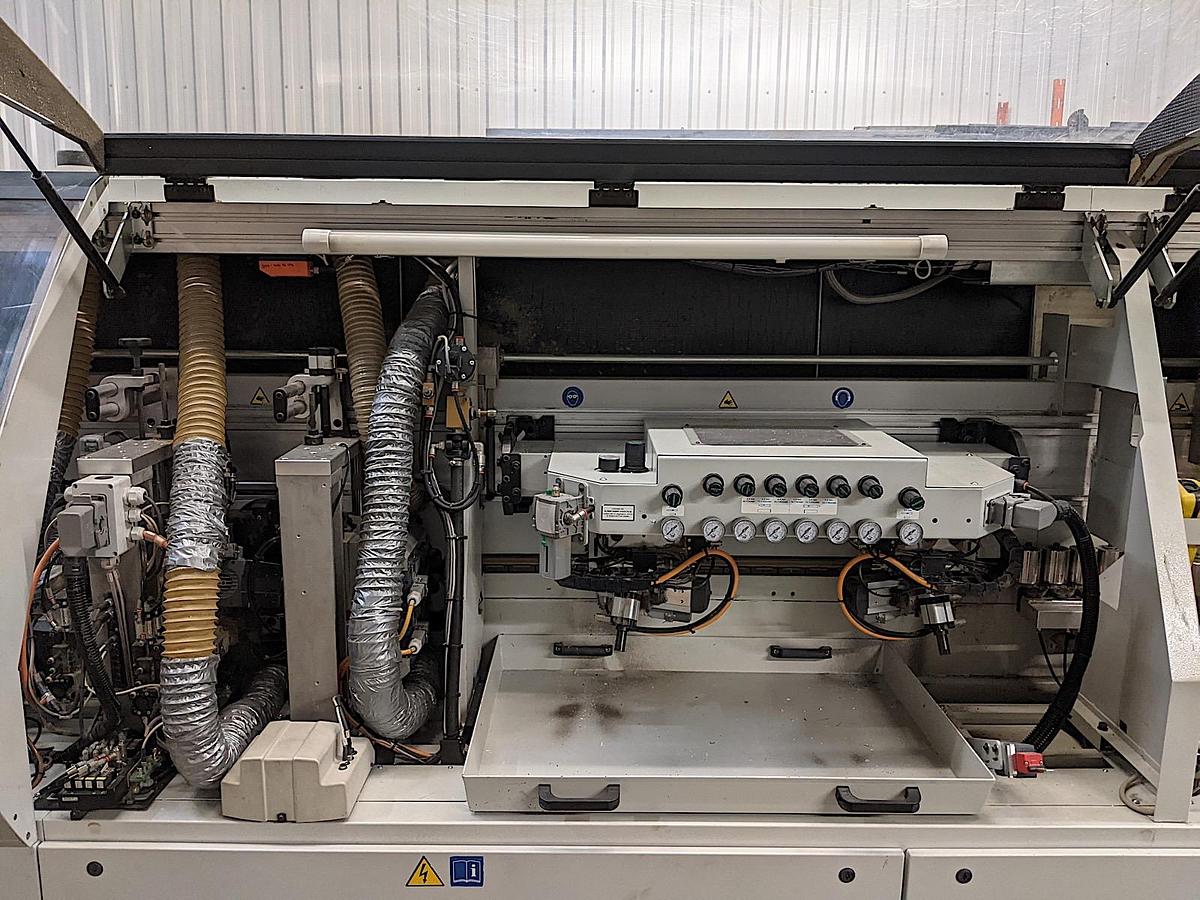

2014 Biesse Roxyl 5.5 AFS Air Force System

2014 Biesse Roxyl 5.5 AFS Air Force System

Available quantity:1

Description

single-sided industrial edgebanding machine designed for applying and processing flat edge-banding materials in rolls (e.g., melamine, PVC, ABS, veneer) and strips (e.g., solid wood, Formica, planed veneers). It features a noise-proof cabin with gluing system VC-710 and TEKNO GLUE system. Space is included for an infeed panel distance spacer with capacitive sensor. It uses PC Flat control system running Windows Professional, available in Italian, English, French, Spanish, or German, with a 17" flat screen (TFT), high-resolution keyboard and mouse, and USB port.

-PC FlatOperating system for control, with dedicated interface, numerical control of axes, writing/running programs, automatic start of units/motors, diagnostics, production stats, video-assisted maintenance.

-Air Conditioning SystemFor the electrical cabinet.

-Belt Presser for Roxyl 5.5Rubber belt with stain-proof coating on springs-housed technopolymer connecting rods.

-Roxyl-Matic HGroup of devices for automatic machine setup, including AX-2 (2 NC axes on infeed fence and 1st pre-milling unit copy-shoe) and AX-1 (1 NC axis on edge pressing rollers RF400).

-Infrared Heating Lamp IRL-700 (2 Lamps)Heats the panel edge before glue application.

-Anti-Adhesive Unit ADZ-700Applies anti-adhesive liquid to top and bottom surfaces for easy cleaning of work piece being processed.

-Pre-Milling Unit FI-502Rectifies the face to be edged, using 2 high-frequency 12000 rpm, 4.7 hp motors with diamond-coated cutters (H=65 mm, ø 80 mm). Includes horizontal/vertical movement of 2 motors on linear guides, independent automatic temporized intervention, air blower for cleaned surface, and AUTO-SET device for optimal positioning.

-Pre-Melt Unit QM-705 for EVA Hot-Melt GlueFacilitates glue color/type changing and feeds glue container; melts at 180°C. Includes granulated glue container (114 l, rapid change), automatic edge feeding for rolls/strips (diameter 900 mm), cutter knife for 3mm max thickness, RPT edge pressing rollers.

-2 Positions Edge MagazineAutomatic edge changement, NC managed; rolls supported by cradle of rollers for quick replace. Includes edge banding strip presence detection device (using photocell).

-Air Force System - Step2Powerful hot compressed air system for edge application (up to 25 m/min speed). Nozzle auto-adjusts for panel thickness (12-60 mm). Compatible with PP + PP coextruded (0.2mm PP), PP + ABS/PVC/PMMA (0.2mm layer), TPU pretreated/preglued edges. Max speed 82 ft/min for 3/4" panel thickness. Installed power 11.5 kW, power consumption 9.5 kW/h, compressed air 12 l/cycle (3 work cycles/h), compressed air requirements 6 bar.

-End Trimming Unit IT-90SComplete with 2 motors for edge trimming; motors tilt 0° to 25° with automatic rotation, pneumatic drive of two end-trimming units.

-Top and Bottom Rough Trimming Unit RS-100Trims top/bottom of applied edge using 2 high-frequency motors complete with self-cleaning rotating vertical copier disks. Feed chain speed 10-25 m/min, panel thickness 10-60 mm.

-Disc Pro-Nesting for RS-100For top/bottom edge trimming; composed of 2 copiers with bearing for processing panels with holes up to max diameter 35 mm and/or grooves.

-Fine-Trimming Unit RF-400Carries out top/bottom trimming of fine finish; complete with front and vertical rotating self-cleaning disk copiers. 2.7 hp (E8000512).

-Disc Pro-Nesting for RF-400For fine trimming; composed of 2 copiers with bearing for panels with holes up to 35 mm diameter and/or grooves.

-Spraying Liquid Application UnitDevice for applying liquid using nozzles above/below the panel. Used for removing/sliding liquid.

-Removing/Sliding LiquidAvoids damaging surface of sensitive edges (acrylic, aluminum) due to contact with copiers; prevents removed during machining operations.

-Multifunction 2 Motors Corner Rounding Unit CR-202, 0.9 hpCarries out corner rounding and top/bottom trimming on panels edged with synthetic material up to max edge thickness of 3 mm. Processes straight profiles and standard post-soft/formed panels with 90° and 180° degrees. High finishing quality; oscillating copying system, frontal copying device with pre-copying system, 4-position fast manual adjustments for 3 thin edges and 1 thick edge (e.g., 3 mm). 2 high-frequency motors 12,000 rpm.

-Pair of Multifunction Cutters for Tilting Trimming UnitPossible operations: chamfering (max 25 degrees) for different thin edges + R=2mm + R=3mm + flush solid wood trimming.

-Edge Scraper RBK-503NC-controlled pneumatic radius change (from 3mm to 2mm and vice-versa). Complete with pneumatic exclusion, carries out finishing on thick PVC/ABS edge-banding strips. Solid steel structure, fast/easy adjustment, mechanical numerical indicators. Includes pair of R=2 mm and R=3 mm knives.

-Disc Pro-Nesting for RBK ScraperEquipped with 3 bearing copiers to permit processing of panels with holes up to a maximum diameter of 35 mm and/or grooves.

-Glue-Scraper RCC-701Auto-aligning with panel surface and auto-adjusting with thickness to remove exceeding glue in the junction panel-edge. Complete with turning discs copying device and flat blade knives. Includes pneumatic exclusion, timed intervention of flat knives, air blowers with nebulized liquid for tool cleaning, dust extraction kit.

-LPT-700 Device for the Application of Cleaning LiquidApplies cleaning liquid on glued edge at end of milling operations for perfect cleaning/polishing. Applied precisely by injectors driven by NC.

-Brushing Unit SP-501Carries out cleaning and polishing of applied edge; includes two 0.37 kW motors/disc brushes at 2800 rpm, tiltable and self-adjusting to the panel height.

-External Hot Air Blower PH-700To reactivate color of thick plastic (e.g., 3mm pvc/abs) after scraping operation. Fitted with two hot air blowers, 2000 W each, with adjustable temperature control.

-Surcharge for Voltage ChangeFor any power supply other than STD.

Specifications

| Manufacturer | Biesse |

| Model | Roxyl 5.5 AFS Air Force System |

| Year | 2014 |

| Condition | Used |

| Stock Number | MA-0815230830-22 |

| Power | 400-600 |